Prototype Mold Makers Manufacturers: Leading the Industry with Innovation

The manufacturing industry stands at the forefront of innovation, continuously evolving to meet the demands of modern consumers. Prototype mold makers manufacturers play a crucial role in this evolution, providing essential services that enable companies to design, test, and manufacture products with precision and efficiency. In this article, we will delve into the significance of prototype mold makers, exploring their impact on various industries, the processes involved, and key considerations when selecting a manufacturer for your business.

The Importance of Prototype Mold Makers

In a world where speed and efficiency are paramount, prototype mold makers serve as the backbone for product development. They create molds that allow businesses to produce prototype parts rapidly, test them for functionality, and make necessary adjustments before mass production. This not only saves time but also significantly reduces costs associated with manufacturing errors and design flaws.

1. Enhancing Product Development

The journey from concept to market requires thorough planning and development. Prototype molds allow manufacturers to:

- Test Designs: Quickly assess the functionality of a product design before committing to large-scale production.

- Modify Rapidly: Make necessary design changes based on prototype testing outcomes, ensuring the final product meets quality standards.

- Reduce Time-to-Market: Accelerate the development process by identifying potential issues early, reducing the overall production timeline.

2. Cost Efficiency

Investing in prototype mold makers manufacturers can lead to significant cost savings. Here’s how:

- Minimize Waste: By testing prototypes, companies can avoid costly mistakes during mass production.

- Lower Materials Costs: Prototype molds can be crafted from less expensive materials, minimizing resource expenditure.

- Streamlined Production: Efficient mold-making processes lead to quicker setup times and reduced labor costs.

Key Processes in Prototype Mold Making

The process of creating a prototype mold is intricate and requires a precise approach to ensure the mold meets specific requirements. Below are the essential steps involved in mold making:

1. Conceptualization and Design

The first step in the prototype mold-making process involves understanding the product requirements. Designers and engineers collaborate to create detailed specifications that include dimensions, materials, and functionality. Advanced CAD (Computer-Aided Design) software is typically used to visualize the mold design.

2. Material Selection

Choosing the right materials for the mold is critical. Common materials include:

- Aluminum: Lightweight and excellent for complex shapes, ideal for short-run productions.

- Steel: Offers durability and is suitable for long-term production molds.

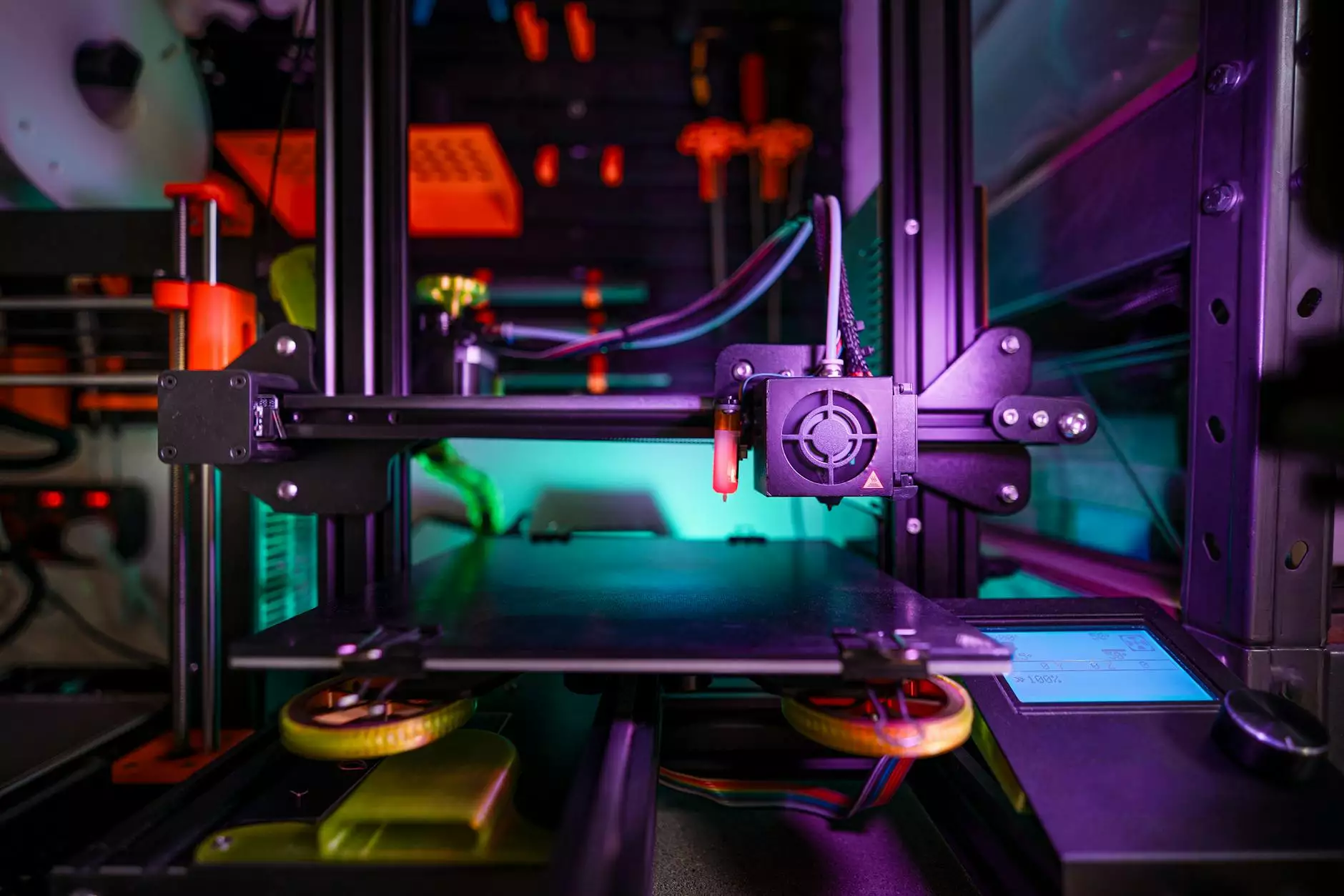

- 3D Printed Materials: Innovative techniques allow for rapid prototyping using 3D printing technology, making it possible to create prototypes quickly and economically.

3. Mold Fabrication

Once the design is finalized and materials are chosen, the actual mold fabrication begins. This step often involves:

- CNC Machining: Utilizing advanced CNC machines to achieve high precision in mold components.

- Injection Molding: Injecting material into the mold to create the prototype, allowing for detailed and consistent outcomes.

4. Testing and Iteration

After the mold is produced, it is tested with actual materials to ensure it meets the desired specifications. This stage is crucial, as it identifies any issues that need to be addressed. Feedback is gathered, and iterations are made as necessary, refining the mold until it meets all requirements.

Choosing the Right Prototype Mold Makers Manufacturer

When selecting a prototype mold makers manufacturer, several factors should be considered to ensure you partner with a company that can meet your needs effectively:

1. Experience and Expertise

Look for manufacturers with a proven track record in your specific industry. Experienced mold makers understand the complexities involved in different applications and can provide tailored solutions that align with your goals.

2. Advanced Technology

Inquire about the technology and equipment that the manufacturer uses. State-of-the-art technology contributes significantly to the precision and quality of the molds produced, as well as the turnaround time.

3. Quality Assurance

Ensure that the manufacturer follows strict quality assurance protocols. This includes testing the prototype molds and implementing continuous improvement practices to maintain high standards.

4. Customer Support

Effective communication and support throughout the process are vital. Choose a manufacturer that is responsive and willing to collaborate closely with your team to address challenges and provide solutions.

The Future of Prototype Mold Making

The field of prototype mold makers manufacturers is continuously evolving, with advancements in technology reshaping the landscape. Here are some trends to watch:

1. Automation and AI

Automation and artificial intelligence are beginning to influence mold-making processes. These technologies can enhance efficiency, reduce human error, and speed up production timelines while maintaining high quality.

2. Sustainable Practices

As environmental concerns grow, many manufacturers are seeking sustainable materials and processes. The adoption of eco-friendly practices not only benefits the planet but also appeals to consumers who value sustainability.

3. 3D Printing Innovations

With the rise of 3D printing in manufacturing, prototype mold makers are exploring new ways to incorporate this technology, offering flexibility and speed in creating molds that were previously challenging to produce.

Conclusion

In summary, prototype mold makers manufacturers are essential partners in the manufacturing process, enhancing product development, reducing costs, and driving innovation. By understanding their importance and selecting the right manufacturer, businesses can achieve significant advantages in today's competitive landscape. As technology continues to evolve, the role of these manufacturers will only become more critical, ensuring that businesses can meet consumer demands with speed and efficiency. Embrace the future of manufacturing by investing in quality prototype mold making to lead your industry into a prosperous tomorrow.