Exploring the Best GBL Cleaner for Adhesive Removal

In today’s fast-paced world, cleanliness and efficiency are paramount, especially for businesses that rely heavily on perfection in their presentations and products. One challenge many industries face is the removal of stubborn adhesives. This is where the best GBL cleaner for adhesive removal comes into play. In this article, we will delve deep into GBL cleaning solutions, their applications, benefits, and how they provide the ultimate solution for adhesive management.

What is GBL?

GBL (gammas-butyrolactone) is a powerful solvent often used in cleaning applications due to its ability to dissolve different types of adhesives that are otherwise challenging to remove. GBL works effectively by breaking down the chemical bonds in adhesives, making cleaning significantly easier. It is particularly favored in industrial settings where efficiency is critical.

Why Use GBL Cleaners

The use of GBL cleaners is not limited to just efficiency; they come with several other advantages:

- High Efficacy: GBL cleaners can tackle the toughest adhesives, including those used in industrial applications.

- Environmental Considerations: Many GBL solutions are designed to be less harmful to the environment compared to traditional solvents.

- Versatile Applications: Suitable for a variety of surfaces, including metals, glass, and plastics.

- Quick Action: GBL cleaners often work faster than traditional adhesive removers, saving time and labor costs.

Applications of GBL Cleaners

GBL cleaners are commonly used across various industries. Here are a few notable applications:

- Manufacturing: Removes adhesive residues from manufacturing equipment.

- Automotive: Ideal for cleaning up adhesive from auto-body repairs.

- Electronics: Cleans circuit boards without causing damage to sensitive components.

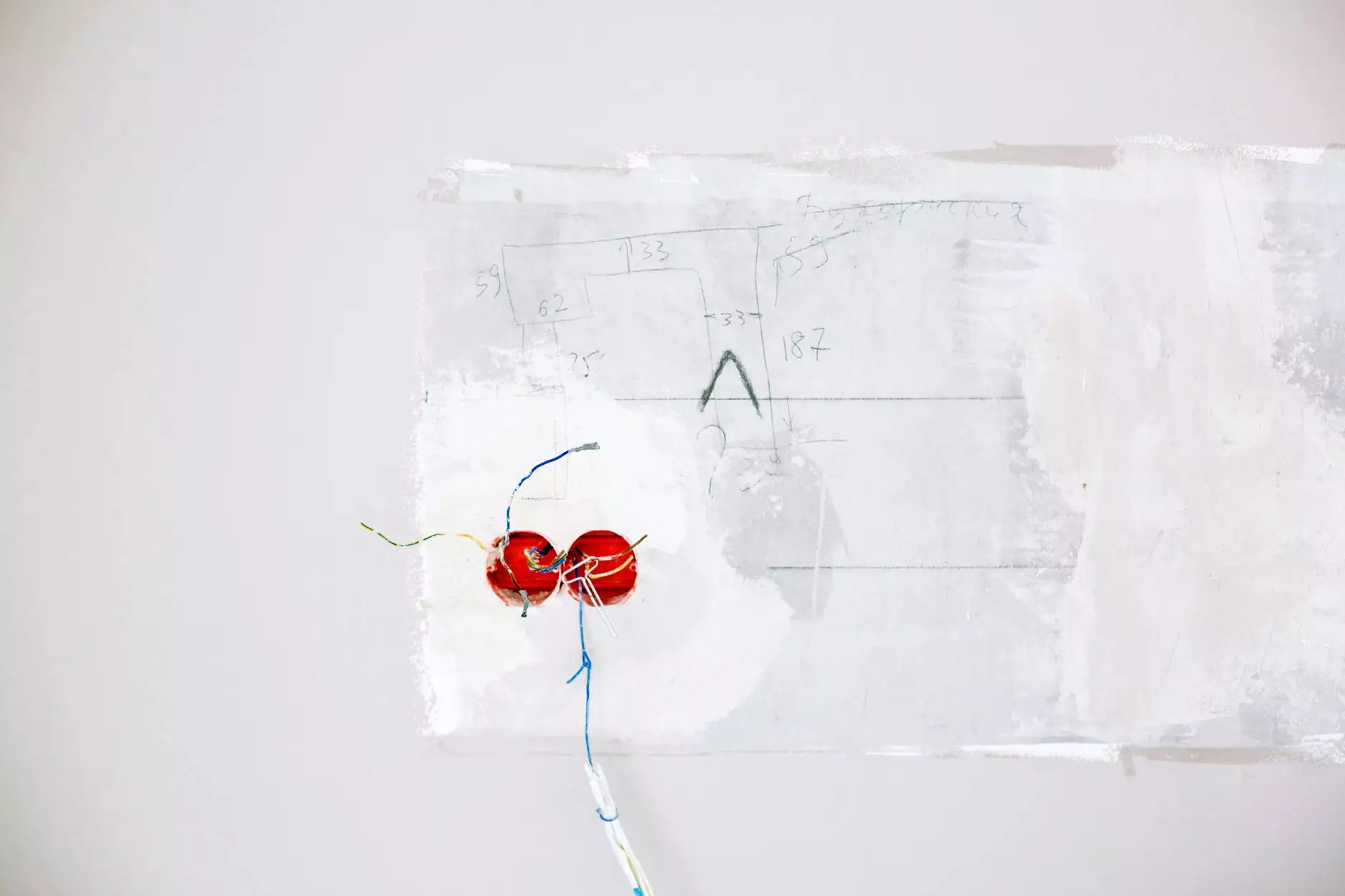

- Construction: Removes construction adhesives from surfaces, preparing them for new applications.

Choosing the Best GBL Cleaner for Adhesive Removal

When selecting the best GBL cleaner for adhesive removal, consider the following factors:

- Composition: Look for cleaners that contain high concentrations of GBL for better efficacy.

- Safety Measures: Choose products that come with safety data sheets (SDS) and follow safety guidelines for handling.

- Surface Compatibility: Ensure that the cleaner is suitable for the materials you are treating to avoid damage.

- Reviews and Recommendations: Opt for brands that have positive feedback from other users in your industry.

Benefits of Using the Best GBL Cleaner for Adhesive Removal

Utilizing the best GBL cleaner for adhesive removal offers numerous benefits, both immediate and long-term:

Efficiency and Speed

GBL cleaners work quickly, often requiring minimal dwell time before the adhesive can be wiped away. This leads to significant time savings in operations.

Cost-Effectiveness

By reducing the time and labor required for adhesive removal, businesses can save money in the long run. This efficiency translates to increased productivity.

Versatility in Application

Different industries have diverse adhesive removal needs. The versatility of GBL cleaners means they can be used across a wide range of applications, making them a valuable asset for any business.

Environmentally Friendly Options

With increasing environmental regulations, many GBL cleaners are formulated to minimize harmful impacts on both health and the environment, allowing businesses to maintain compliance with regulations while achieving effective cleaning.

How to Use GBL Cleaners Effectively

To maximize the effectiveness of GBL cleaners, follow these steps:

- Preparation: Wear appropriate personal protective equipment (PPE), including gloves and goggles, before starting the cleaning process.

- Application: Apply the GBL cleaner directly onto the adhesive residue or onto a cloth. Ensure complete saturation for thorough cleaning.

- Dwell Time: Allow the cleaner to sit for a specified time (usually a few minutes) to penetrate the adhesive.

- Removal: Use a clean cloth or scrape gently with a plastic scraper to remove the dissolved adhesive.

- Final Rinse: If necessary, rinse the area with water or a suitable solvent to ensure no residue remains.

Safety Precautions When Using GBL Cleaners

Safety should always be a priority when handling any cleaning chemicals, including GBL cleaners. Here are essential safety precautions:

- Ventilation: Ensure the workspace is well-ventilated to reduce inhalation risks.

- Storage: Store GBL cleaners in a cool, dry place away from direct sunlight and heat sources.

- Disposal: Follow local regulations for the disposal of chemical cleaners to ensure environmental compliance.

- First Aid: Familiarize yourself with first aid measures in case of exposure.

Top GBL Cleaners for Adhesive Removal

Here, we present a list of some highly recommended GBL cleaners available on the market that excel in adhesive removal:

- Product A: Known for its fast-acting formula and minimal surface damage.

- Product B: Appreciated for its eco-friendly ingredients and versatility.

- Product C: A great choice for heavy-duty adhesive removal in industrial environments.

Conclusion

In conclusion, the best GBL cleaner for adhesive removal can significantly enhance operational efficiency within your business. By choosing the right product and following proper application and safety techniques, you can ensure effective cleaning while maintaining a safe working environment. Investing in high-quality GBL cleaners is an investment in productivity, safety, and long-term success. For more information and to explore top GBL cleaning solutions, visit gblcleanershop.com.